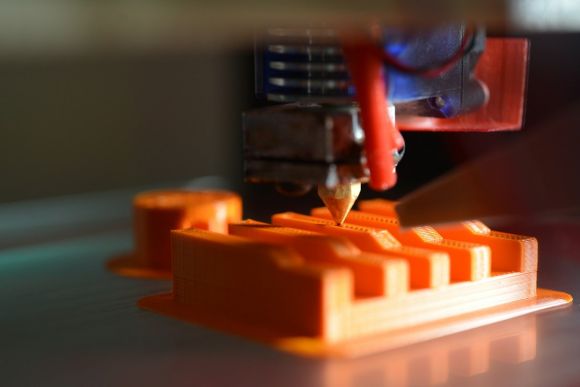

In recent years, 3D printing has emerged as a groundbreaking technology with the potential to revolutionize the manufacturing industry. This innovative process, also known as additive manufacturing, allows for the creation of three-dimensional objects from digital designs. With its ability to produce complex shapes and structures with great precision, 3D printing has opened up a world of possibilities for manufacturers. In this article, we will explore the implications of 3D printing in manufacturing and discuss its potential impact on various industries.

Streamlining the Design Process

One of the key advantages of 3D printing is its ability to streamline the design process. Traditionally, manufacturers would have to create prototypes using costly and time-consuming methods such as CNC machining or injection molding. With 3D printing, designers can quickly and inexpensively produce prototypes and iterate on their designs much faster. This allows for more efficient product development cycles and ultimately leads to shorter time-to-market.

Reducing Manufacturing Costs

Another significant implication of 3D printing in manufacturing is the potential to reduce costs. By eliminating the need for tooling and molds, manufacturers can save on upfront expenses. Additionally, 3D printing enables on-demand production, meaning that items can be produced as needed, reducing inventory costs. This flexibility also allows for customization and personalization, which can lead to increased customer satisfaction and loyalty.

Enabling Complex Geometries

The ability to create complex geometries is perhaps one of the most exciting implications of 3D printing in manufacturing. Traditional manufacturing methods often have limitations when it comes to producing intricate designs. With 3D printing, however, designers can easily create complex shapes and structures that were once thought to be impossible. This opens up new possibilities for product innovation and allows for the creation of unique and customized products.

Enhancing Sustainability

3D printing also has significant implications for sustainability in manufacturing. Traditional manufacturing processes often result in a considerable amount of waste, as excess material is cut away or discarded. In contrast, 3D printing is an additive process, where material is only used where it is needed. This reduces waste and can lead to more sustainable production practices. Additionally, 3D printing can enable local production, reducing the need for long-distance shipping and decreasing the carbon footprint associated with transportation.

Disrupting Supply Chains

The implications of 3D printing are not limited to the manufacturing process itself but extend to the entire supply chain. By enabling on-demand production, 3D printing has the potential to disrupt traditional supply chain models. Instead of relying on centralized production facilities and long shipping times, manufacturers can produce items closer to the point of consumption. This can lead to shorter lead times, reduced inventory, and greater supply chain flexibility.

Conclusion: Embracing the Future of Manufacturing

As we have explored in this article, the implications of 3D printing in manufacturing are vast and far-reaching. From streamlining the design process and reducing costs to enabling complex geometries and enhancing sustainability, 3D printing has the potential to transform the way products are made. As this technology continues to evolve and become more accessible, it is crucial for manufacturers to embrace it and capitalize on its benefits. By doing so, they can stay ahead of the competition and shape the future of manufacturing.